Building

A

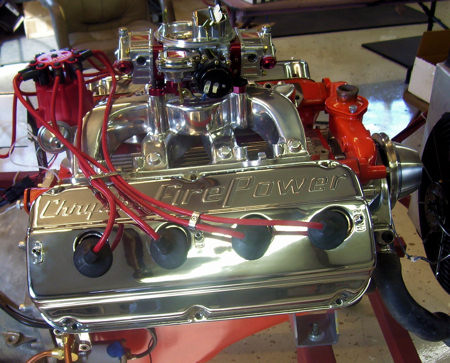

Chrysler Firepower Hemi

'354'

Chrysler Hemi Build

(First Generation Hemi)

Step I

** After buying 3 Hemis you may have enough parts to build a NE 56 354' CU

IN Hemi **

Step II

Contact Bob Walker at Hot Heads Research for

technical assistance and top quality parts.

http://www.hothemiheads.com/

and

Find a top quality High Performance Machine Shop

Remember -- You get what you pay for...

I used my race engine machinist from my old Super Gas Days in the late 70s.

Eddie Browder of Ed's Machine and Performance , Abilene,

Texas

http://www.edsmachine.com

Step III

Get you

prep work done and then deliver engine to machine shop.

|

|

Get what

you need to do - done - before taking it all to the machine shop. Such as:

I Polished the Rod Beams, Ed and Oscar will install 440 ARP rod bolts, shot

ping, resize

the big ends and install new bushings in the small ends of the rods. A smooth

surface is stronger

than a rough surface.

Step

IV

Parts All Ordered

and

Engine Back From Machine Shop

|

|

Engine and Rods are now back from

the machine shop, with the rods shot pinged and rebuilt with new rod

bolts. Ross Pistons were special ordered through Bob Walker. Bob took the

block's deck height to center

of crankshaft, and cylinder heads cc and deigned a set of Ross Forged pistons

for 10.3 to 1 compression.

The max compression you can run with pump gas and the old iron heads. We built

a set of "555" heads for

this Hemi. See more on heads later. Inkenderian Cam 480 lift cam on 108 center

lobe which dialed in at

107 center lobe on o keyway. (Solid lifters with adjustable push rods.) Engine

assembly is Balanced

Chrysler 1956 - 354' New Yorker Hemi AKA --- "NE 56" |

|

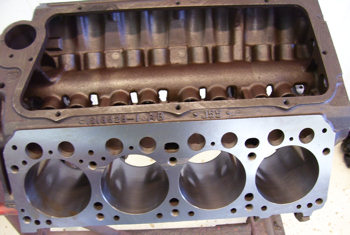

The Mains were true so this block did not have to be line bored. The crank

turned over really nice

once installed with a "Best Gasket" neoprene rear main seal. Main

Stud Kit was used instead of

stock main bolts.

|

|

Block Decked and bored on a CNC mill. Two Torque plates, one for each side,

were torqued onto the block before

the cylinders were power honed for 4" Seal Power moly rings. The pistons

were designed and the block bored

to 4 inches so the pistons could be designed with stock sized 350 Chevrolet

piston ring grooves. Reason is that

only cast and chrome rings are available for the .060 over 354 bore. The 4"

bore is only a few thousands larger.

and the selection of piston rings is unlimited. Five thousand clearance between

the pistons and cylinder walls.

Deck height .014.

Step V

Select Your Engine Builder

Paul says, "I may be left handed, but I'm gooood at what I do and I Love Hemi s ". (First Three Days of build.) |

|

|

|

|

See Movie at bottome of page. |

|

Well...... If you

are a grandfather, we all know who is going to be the engine builder.

Paul's first Engine Build and it's a First Generation Hemi!!!!!!

How many people can claim those bragging rights... At the age of 9...

Step VI

Heads and Rocker

Arm Assembly

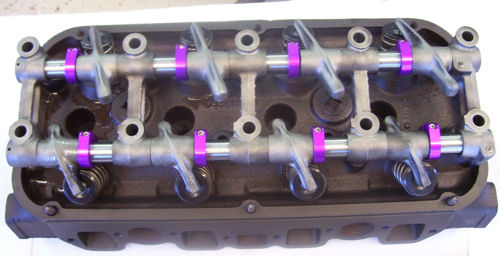

Head Machined with angle Competition

Valve Job by:

Oscar

at Edsmachine.com

|

Heads are the preferred"555" or "Triple Nickel Heads" 3x5 # |

Intake Valve and Spring with seal. Stainless swirl polished valves. |

Exhaust Valve and Spring without Seal |

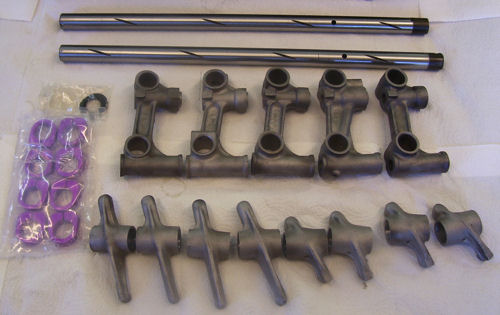

I decided we would do the Rocker Arm Assemblies, outselves. Paul beaded the

rockers and posts. I polished the shafts on the Lath and honed the insides of the

rockers. I assembled one Rocker arm set, to teach Paul, and then grandson

Paul assembled the other rocker arm set. (See Movie at bottom of page)

Purple collars to eliminate the stock spring assemblies were ordered from Hot Heads.

Movies of the Hemi Build

|

|

|

|

|

|

|

|

|

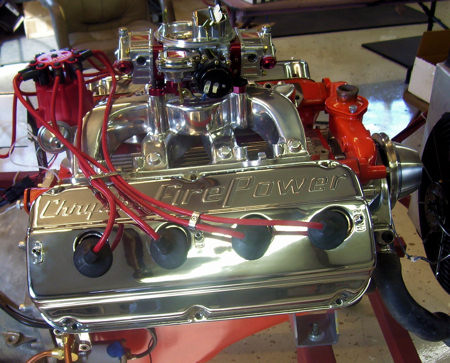

Coming Together - The Eye Candy

Hot Head's Intake, Timing Cover, Balancer, Pulleys, Valley Cover and Alternator Bracket. I ordered the Valley Cover already polished but I polished the Intake, and Timing Cover. Be sure you really want to do your own polishing work before you start. I had three full days in the Intake alone and almost a full day in the timing cover. Counting supplies, ordering them all already polished would have been cheaper, I think. A short Big Block Chevy Water Pump is ordered. I will have to polish it myself as well. |

|

|

|

|

MSD "Ready to Run" ignition, Taylor Plug Wire, 426 Spark Plug Boots, and 680 Quick Fuel Carb set up by RPM Performance. '57 392 water cross over with brackets ground off and smoothed up. AND A WHOLE LOT OF ELBOW GREASE... |

Click

Here to See Page 1

53 Plymouth Gasser Body Work Update